Zn Metals SIA tērauda karstā cinkošana un duplex pārklājums.

Guidance

1. Choosing the right material

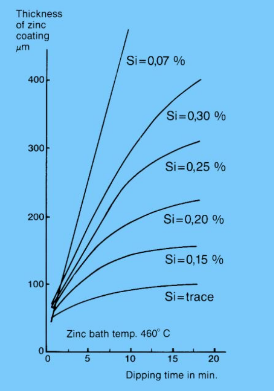

The determining factor when choosing a metal suitable for galvanizing is the silicon (Si) content, which should preferably be in the range of 0.15-0.21%. It is also necessary to take into account the thickness of the metal, since the thickness of the zinc coating depends on it.

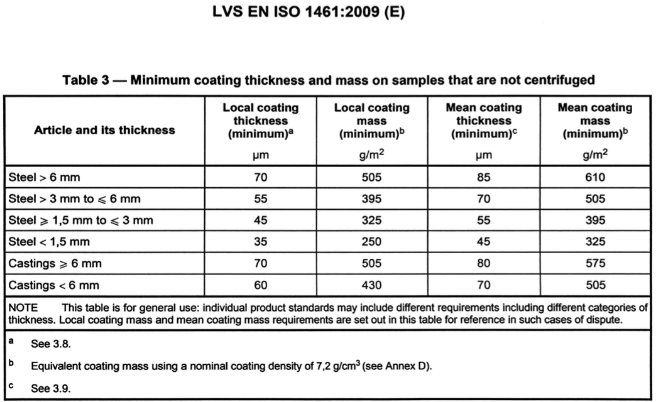

We provide minimum coating thickness as per ISO standard.

2. Preparation of structures for galvanizing

Metal structures should preferably be prepared in accordance with ISO 1090, paying particular attention to the quality of the welds and post-welding treatment.

Often new steel products are coated with preservative oils or paint systems. In this case, the surface must be cleaned before galvanizing. The paint is cleaned using an abrasive jet, while lubricating oils are chemically removed before galvanizing. Heavily rusted surfaces must also be cleaned before galvanizing.

You should pay attention to the correct choice of chemical auxiliaries:

Consequences of using the wrong anti-splash aerosol on galvanized products!

It is advisable to choose a plant-based anti-splash product:

Consequences of using an incorrect anti-spatter spray for galvanized products!

It is advisable to choose a plant-based anti-splash product:

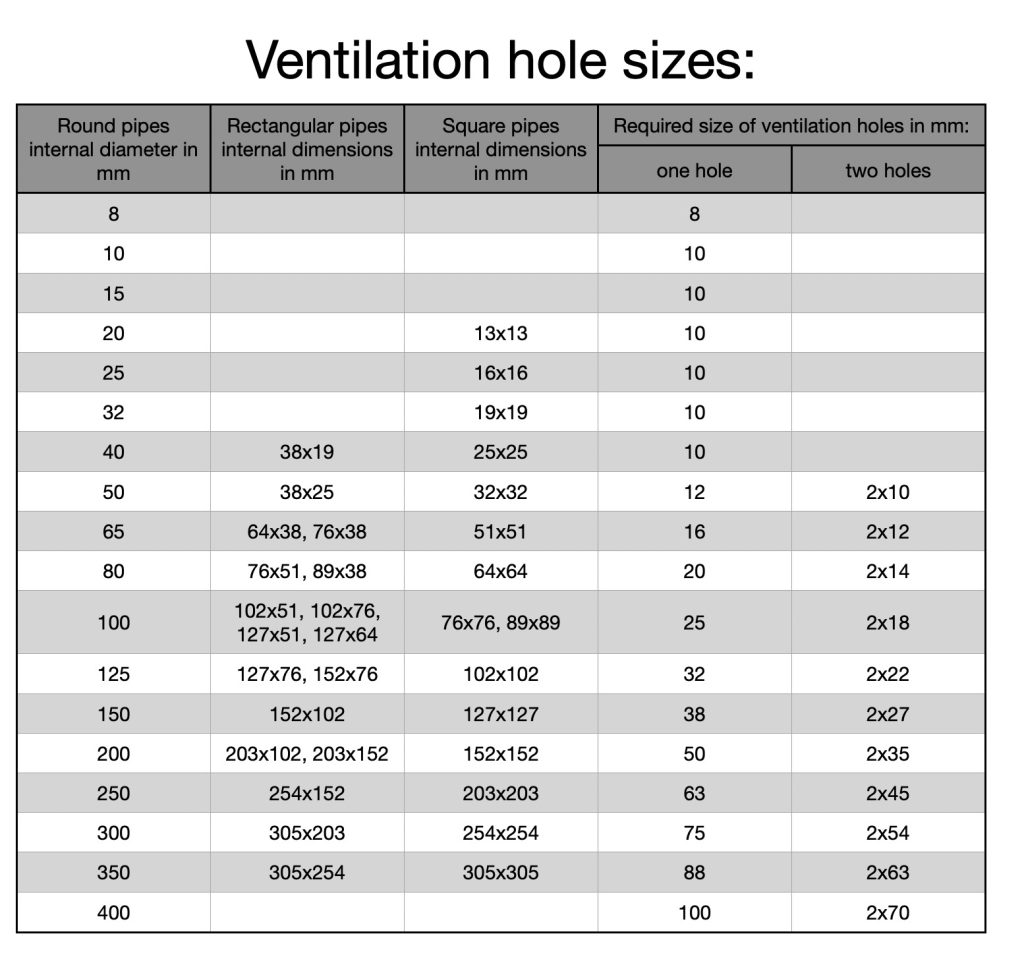

3. Ventilation holes

Correctly selected dimensions and location of process holes are essential for the quality of galvanizing, especially in hollow structures.

If the holes need to be closed after galvanizing, we suggest using aluminum plugs.

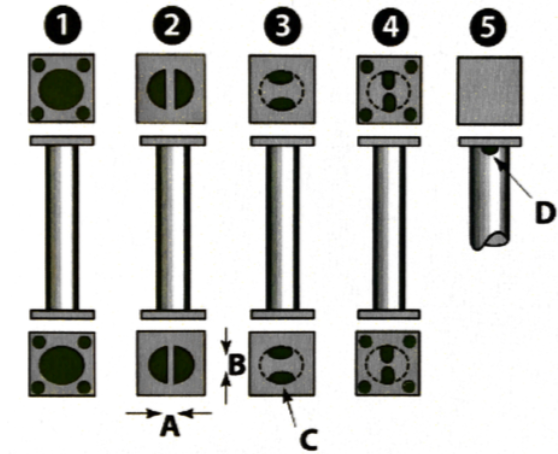

Images showing hole locations in the most popular/common types of designs:

Pictures showing the location of holes in the most popular/most common types of structures:

4. After galvanizing

The most common visual problems after galvanizing that do not affect corrosion protection are: “white rust” (zinc oxide), zinc stains and acid stains.

“White rust” is characteristic of freshly galvanized steel and appears in the form of whitish spots of uneven shape on the galvanized surface, which are easily washed off.

These are zinc oxidation products that occur when freshly galvanized steel comes into contact with water and carbon dioxide. White stains should be washed off with water or wiped off with a fine abrasive product. The freshly galvanized product should be placed in a dry, well-ventilated place.

On galvanized parts you can observe smudges that occur when the zinc is removed from the bath and quickly cools. This is inevitable phenomenon, which can be avoided at the stage of mechanical post-treatment of a galvanized part.

If the product has welded parts, then, during its treatment with hydrochloric acid, hydrochloric acid reaction products remain underneath it, which are not completely removed during the galvanizing process and may appear after galvanizing in the form of brown, rusty smudges.

This phenomenon is called “rust bleeding” and can be prevented by mechanical friction and rinsing of the treated surface.

In case of any confusion or additional questions, please contact our managers!

It is important to remember that the primary purpose of galvanizing is protection against corrosion and appearance is of secondary importance (Section 6.1, ISO1461).